Servo Based Control System services

At Pulse Control, we specialize in delivering advanced servo-based control systems designed to elevate the precision, efficiency, and performance of your operations. Whether you’re in manufacturing, robotics, aerospace, or any other industry that demands high levels of accuracy and control, our servo-based solutions provide the reliable and powerful automation you need.

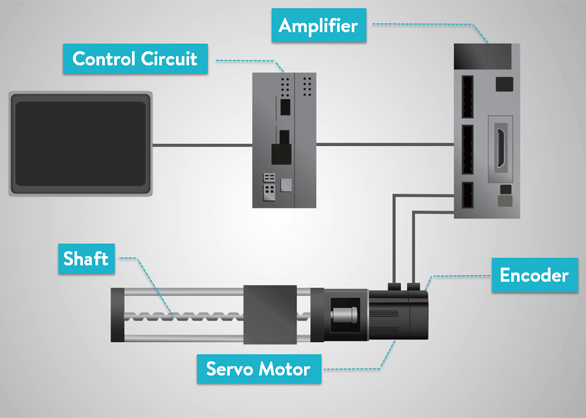

Servo-based control systems are integral in managing motion, speed, torque, and position with exceptional accuracy. By utilizing advanced technology, these systems enable businesses to enhance productivity while minimizing errors and downtime. Pulse Control offers comprehensive services that include design, installation, optimization, troubleshooting, and support, ensuring that your servo system operates at peak performance.

Our team of experts works closely with you to understand your specific requirements and tailor a solution that meets your needs. With Pulse Control’s servo-based control system services, you can expect seamless integration, ongoing technical support, and long-term reliability that helps your business stay ahead in a competitive market.

The Importance of Servo-Based Control Systems

Servo-based control systems play a pivotal role in industries that require precise control of motion, speed, and torque. From manufacturing plants and automated machinery to robotics and aerospace applications, these systems are integral to ensuring optimal performance, efficiency, and accuracy. In this section, we will explore the significant importance of servo-based control systems and why they are critical in today’s advanced industrial and technological landscapes.

Precision and Accuracy

One of the most important features of servo-based control systems is their ability to deliver precise and accurate control. These systems provide real-time feedback, allowing for continuous adjustments to ensure that the motor’s position, speed, and torque match the desired setpoints with minimal deviation. This level of precision is essential in industries like CNC machining, robotics, and medical equipment manufacturing, where even the slightest error can lead to costly mistakes or defects.

In manufacturing processes such as 3D printing, laser cutting, and assembly line operations, servo systems are used to execute highly intricate tasks, delivering flawless results. The feedback loop in a servo control system constantly monitors the motor’s performance, making corrections instantly to maintain precision, which ultimately leads to better quality products and fewer production errors.

Speed and Performance

Servo-based control systems are designed for high-speed performance, which is crucial in industries that require rapid movement and quick response times. The closed-loop feedback system ensures that the servo motor adjusts its speed in real time based on the input signal and the desired position or speed.

For example, in robotic arms used in industrial automation, servo systems allow for rapid acceleration, precise deceleration, and flawless speed control, all of which enable faster production cycles without compromising on accuracy. This speed and responsiveness are also critical in industries like aerospace, where systems must quickly adjust to dynamic conditions.

Efficiency and Energy Savings

Servo motors are more energy-efficient than traditional motors because they only consume power as needed. Unlike other motors that run continuously at full power, even when not required, servo motors adjust their power consumption based on the load and performance needs. This results in lower energy consumption and reduced operational costs.

For businesses looking to reduce energy waste and improve sustainability, servo-based systems offer significant savings. The dynamic efficiency of servo motors ensures that your business operates at optimal levels, minimizing unnecessary energy expenditure while enhancing overall performance.

Reduced Wear and Tear

In traditional motors, the lack of precise control over movement can cause unnecessary stress and wear on mechanical components. With servo-based systems, the precise motion control helps reduce the amount of mechanical strain placed on the equipment. The system ensures smooth acceleration and deceleration, preventing sudden jerks or movements that could cause mechanical components to wear out prematurely.

This is particularly beneficial in high-cycle applications, such as automated production lines or robotic systems, where constant movement and precision are essential. By reducing mechanical wear, servo systems extend the lifespan of the equipment, which can save businesses substantial amounts in maintenance and replacement costs over time.

Versatility and Flexibility

Servo-based control systems are highly versatile, capable of controlling a wide range of applications. They are not limited to any particular type of industry but can be tailored to meet the specific needs of various sectors. For example:

- Robotics: In robotics, servo motors are crucial for creating precise movements in robotic arms and legs, ensuring accurate assembly, manipulation, and packaging.

- Automotive Industry: Servo systems are used in automotive assembly lines to automate tasks such as welding, painting, and part assembly, which require both precision and speed.

- Medical Equipment: Servo motors are also used in medical devices like MRI machines, where precise positioning of components is critical for patient safety and effective operation.

This flexibility allows businesses across industries to implement servo-based systems in their operations, boosting productivity and enhancing the quality of their products and services.

Integration with Other Systems

Another key benefit of servo-based control systems is their ability to integrate seamlessly with other systems, including PLC (Programmable Logic Controllers), HMI (Human-Machine Interface), and SCADA (Supervisory Control and Data Acquisition) systems. This integration ensures that the servo systems work in harmony with other equipment and processes in a factory or automated setup.

For example, in a manufacturing plant, a servo-based system can work in tandem with a PLC to control assembly line movements, with a HMI providing operators with real-time data and control over the system’s performance. The ability to integrate with other technologies enhances operational efficiency, reduces the risk of errors, and provides centralized control over multiple processes.

Pulse Control’s Servo-Based Control System Services

At Pulse Control, we specialize in providing cutting-edge servo-based control systems services designed to meet the specific needs of your business. Our services focus on offering robust and reliable solutions that enhance your operational efficiency, reduce downtime, and increase precision.

Design and Installation:

We work with you to design a custom servo-based control system tailored to your specific requirements. Our team of experts ensures that the system is seamlessly integrated into your existing infrastructure, offering maximum efficiency and ease of use.

System Optimization:

Our servo control systems are built for performance, but over time, even the best systems can benefit from optimization. Pulse Control offers regular maintenance and optimization services to ensure that your system operates at peak performance, with minimal downtime and maximum reliability.

Troubleshooting and Repairs:

If issues arise with your servo-based control system, Pulse Control is here to provide fast, effective troubleshooting and repair services. Our team diagnoses problems quickly, reducing downtime and restoring your system to its optimal state.

Training and Support:

To ensure that your team can operate and maintain the system effectively, Pulse Control offers comprehensive training and ongoing technical support. We equip your operators and technicians with the knowledge they need to get the most out of your servo-based control system.

Upgrades and Retrofits:

As technology evolves, so should your systems. Pulse Control provides upgrade and retrofit services, allowing you to take advantage of the latest advancements in servo control systems without replacing your entire setup.

Servo-based control systems are indispensable in today’s fast-paced, precision-driven industries. With their ability to deliver unmatched accuracy, speed, and efficiency, they are the backbone of automation in sectors ranging from manufacturing to robotics. Pulse Control is committed to helping businesses harness the full potential of servo-based control systems through expert design, installation, optimization, and support services. By adopting servo-based control systems, you can ensure that your operations are more efficient, reliable, and future-proofed, driving long-term success.

If you’re looking to integrate or optimize a servo-based control system, Pulse Control has the expertise and experience to help you every step of the way.