Machine Retrofit services

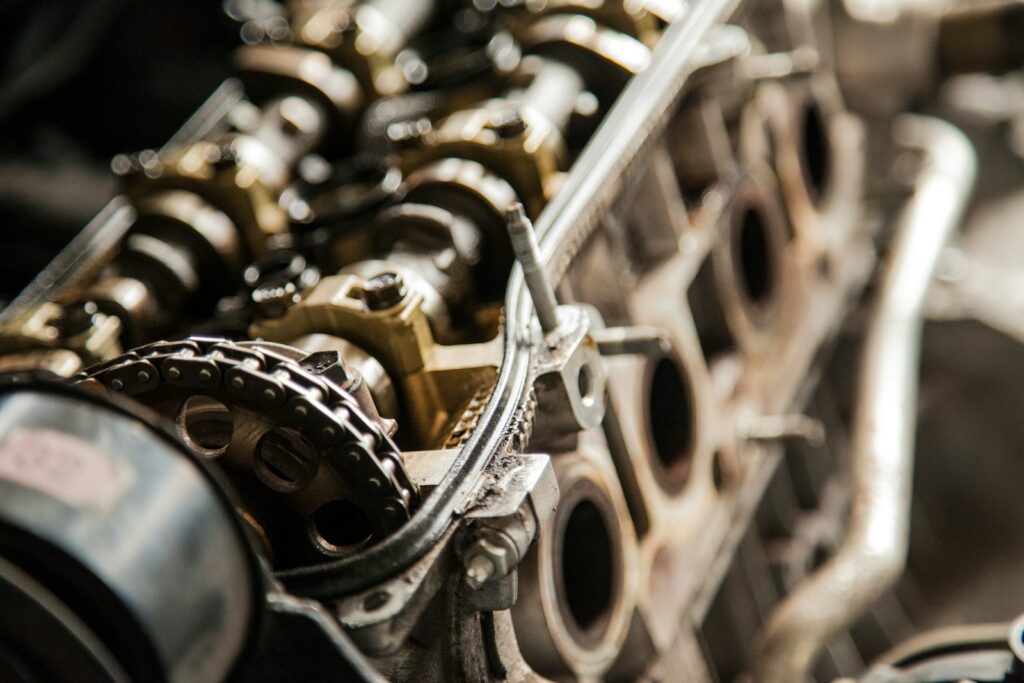

Machine retrofit services play a critical role in modernizing and enhancing industrial machinery, ensuring that older equipment remains functional, efficient, and competitive in today’s technologically advanced world. A retrofit involves upgrading the components or systems of existing machinery, often by integrating advanced technology or replacing outdated parts. This process extends the life of machinery, improves performance, and reduces the need for costly new equipment purchases.

One of the primary benefits of machine retrofit services is the significant cost savings compared to replacing entire machines. Industries with extensive investments in large-scale machinery, such as manufacturing, automotive, or construction, often face substantial expenses when equipment becomes outdated. Retrofitting allows these businesses to achieve modern functionality without incurring the full cost of new machinery. For instance, adding advanced control systems, such as PLCs (Programmable Logic Controllers), VFDs (Variable Frequency Drives), or IoT (Internet of Things) sensors, can enhance precision, automate processes, and improve overall productivity.

Additionally, retrofitting addresses challenges related to obsolescence. Many machines, while mechanically sound, operate using components that are no longer manufactured or supported. Through retrofitting, companies can replace these obsolete parts with modern alternatives, ensuring continuity and reducing downtime. For example, outdated hydraulic systems might be upgraded with electric or hybrid solutions, improving energy efficiency and environmental compliance.

Another advantage lies in sustainability. Retrofitting older machines to meet current energy and safety standards can significantly reduce their environmental footprint. By optimizing power usage or introducing smart technologies, companies can achieve substantial energy savings, which is increasingly important in industries striving for greener operations. This approach also aligns with regulatory requirements, avoiding potential fines or penalties.

Machine retrofit services are also highly customizable, catering to the specific needs of each industry. Whether it involves enhancing speed, accuracy, or output capacity, retrofitting can be tailored to meet unique operational demands. For example, in the food processing industry, retrofitting might involve upgrading conveyor systems to improve hygiene and efficiency. In the automotive sector, it could mean enhancing robotic arms with advanced sensors to increase assembly line precision.

Moreover, retrofitting reduces operational disruption. Unlike purchasing and installing new machines, which often require lengthy setup and training periods, retrofitted equipment generally integrates seamlessly into existing workflows. Technicians can upgrade components on-site, minimizing downtime and maintaining productivity.

In conclusion, machine retrofit services are a strategic investment for businesses aiming to maximize the lifespan and utility of their machinery while adapting to evolving technological, economic, and environmental demands. By embracing retrofitting, companies not only save money but also enhance their operational capabilities, future-proof their assets, and contribute to sustainable practices in their industries.

Machine Retrofit Services in Pulse Control

Pulse Control is a leading provider of machine retrofit services, offering innovative solutions to modernize industrial equipment and optimize operational efficiency. With expertise in integrating advanced technologies and a deep understanding of various industries, Pulse Control helps businesses extend the life of their machinery, reduce costs, and adapt to evolving technological demands.

Comprehensive Retrofit Solutions

Pulse Control specializes in retrofitting a wide range of industrial machines, from manufacturing equipment to automation systems. Their services include upgrading obsolete components, such as outdated control systems, motors, and drives, with modern alternatives. For example, they frequently integrate Delta PLCs, Variable Frequency Drives (VFDs), and industrial sensors, ensuring enhanced automation, precision, and energy efficiency.

Customization and Industry Expertise

The company provides tailored retrofit solutions to address specific operational needs. Whether it’s increasing production speed, enhancing system accuracy, or integrating Industry 4.0 capabilities, Pulse Control delivers solutions that align with each client’s objectives. Their expertise spans industries such as manufacturing, automotive, food processing, and energy, ensuring a deep understanding of sector-specific challenges and requirements.

Integration of Advanced Technologies

Pulse Control emphasizes integrating cutting-edge technologies, such as IoT-enabled devices, SCADA systems, and AI-based monitoring tools. These upgrades not only enhance machine functionality but also enable real-time monitoring and predictive maintenance. For instance, adding IoT sensors to older equipment provides actionable data insights, helping businesses proactively address issues before they escalate into costly downtime.

Energy Efficiency and Sustainability

As industries aim for greener operations, Pulse Control’s retrofit services often focus on improving energy efficiency. By replacing inefficient motors with high-performance alternatives or upgrading control systems, companies can significantly reduce energy consumption. Pulse Control ensures compliance with energy standards, contributing to a reduced environmental footprint while lowering operational costs.

Seamless Implementation

Pulse Control’s retrofit services are designed to minimize disruption. Their team of experts conducts upgrades on-site, ensuring minimal downtime and seamless integration with existing workflows. This approach is particularly beneficial for industries that rely on continuous production, as it avoids the lengthy setup times associated with purchasing and installing new equipment.

Long-Term Benefits

Retrofitting through Pulse Control not only enhances machine performance but also ensures compliance with industry standards and extends the lifespan of equipment. Clients benefit from reduced maintenance costs, improved safety features, and a competitive edge in their operations.

In summary, Pulse Control’s machine retrofit services offer a cost-effective, sustainable, and technologically advanced solution for modernizing industrial equipment. By partnering with Pulse Control, businesses can maximize the value of their assets, improve efficiency, and stay ahead in an increasingly competitive market.

Key Advancements in Retrofit Services

Integration of Smart Technologies

- IoT and IIoT (Industrial Internet of Things): Retrofitted machines are now equipped with IoT-enabled sensors that allow real-time monitoring, data collection, and predictive analytics. This capability helps in minimizing downtime by identifying potential issues before they become critical.

- AI and Machine Learning: AI-driven systems can optimize machinery processes by learning from operational patterns. They improve efficiency, reduce waste, and allow for adaptive control strategies, making older machines perform at par with modern equipment.

Digital Twin Technology

- Retrofits now often include the development of digital twins, virtual replicas of physical machines. These digital twins enable simulation, performance testing, and predictive maintenance, ensuring that the retrofitted equipment operates optimally under various conditions.

Advanced Control Systems

- Modern retrofitting incorporates high-speed PLCs, VFDs, and SCADA systems to automate and streamline processes. These control systems enhance precision, improve output quality, and allow seamless integration with existing setups.

Energy Efficiency Upgrades

- Retrofitting now includes replacing energy-intensive components with high-efficiency alternatives like servo motors or regenerative drives. Additionally, smart energy management systems are integrated to monitor and optimize power consumption in real-time.

Augmented and Virtual Reality (AR/VR):

- AR/VR technologies are used for training operators on retrofitted machines, simulating operational scenarios, and assisting in complex installations. This advancement ensures smooth adaptation and maximized productivity post-retrofit.

Cybersecurity for Retrofitted Systems

- With digital advancements, retrofits also address cybersecurity. Secure communication protocols and firewalls are integrated to protect IoT-connected machinery from cyber threats, ensuring data safety and operational continuity.

The advancements in retrofit services make them a vital tool for industries looking to stay competitive and sustainable in a fast-evolving technological landscape. By integrating smart systems, energy-efficient solutions, and advanced automation, retrofitting transforms existing machinery into high-performing assets.