Unlocking the Future of Efficiency with Industrial Automation

In today’s fast-paced industrial world, the need for operational efficiency, precision, and speed is more critical than ever. Businesses are under constant pressure to reduce costs, increase output, and improve the quality of their products—all while staying competitive. Industrial automation offers a powerful solution to these challenges, providing companies with the tools they need to streamline their processes and drive growth. At Pulse Control, we specialize in delivering cutting-edge industrial automation services that help businesses unlock new levels of productivity and efficiency.

What is Industrial Automation?

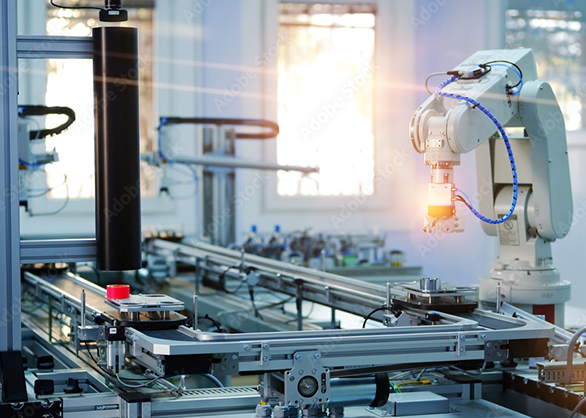

Industrial automation refers to the use of control systems—such as computers, robots, and information technologies—to manage and control industrial processes and machinery. By automating tasks that would typically require human intervention, businesses can achieve faster, more consistent, and cost-effective operations. Automation is used across a variety of industries, including manufacturing, energy, food processing, pharmaceuticals, and more.

Benefits of Industrial Automation

The implementation of industrial automation brings numerous advantages to businesses, including:

Increased Efficiency and Productivity

Automation enables machines to perform tasks faster and more accurately than humans. By automating repetitive and time-consuming tasks, businesses can significantly increase production rates, reduce downtime, and improve overall operational efficiency.Cost Reduction

While the initial investment in automation technologies may be significant, the long-term cost savings are substantial. Automation reduces the need for manual labor, decreases the likelihood of errors, and cuts down on material waste, leading to a more cost-efficient operation.Improved Product Quality

Automated systems are designed for precision, ensuring that tasks are completed to exact specifications every time. This leads to more consistent and higher-quality products, which is crucial for maintaining customer satisfaction and meeting regulatory standards.Enhanced Safety

By automating hazardous tasks or tasks performed in dangerous environments, industrial automation minimizes the risk to human workers, thereby improving workplace safety and reducing the likelihood of accidents.Data-Driven Insights

Industrial automation systems generate a wealth of data that can be analyzed to improve operations. Businesses can use this data to monitor performance in real time, identify bottlenecks, and make data-driven decisions that improve overall productivity.

Pulse Control’s Industrial Automation Services

Pulse Control offers a comprehensive range of industrial automation services designed to meet the unique needs of each client.

1. PLC Programming and System Integration

Programmable Logic Controllers (PLCs) are the backbone of many automated systems. Pulse Control’s team of experts specializes in programming and integrating PLC systems to ensure they work seamlessly with existing machinery, improving control and communication between various systems. We also provide custom solutions that can be tailored to your specific needs.

2. SCADA Systems for Real-Time Monitoring

Supervisory Control and Data Acquisition (SCADA) systems provide real-time data monitoring and control for your entire production line. Our SCADA solutions allow businesses to remotely manage equipment, track performance metrics, and make adjustments on the fly. By utilizing SCADA, your team can ensure smoother operations and avoid costly downtime.

3. Predictive Maintenance

With Pulse Control’s predictive maintenance services, businesses can monitor equipment health in real time and anticipate when a machine might fail. This proactive approach minimizes unplanned downtime, extends equipment lifespan, and reduces maintenance costs.

4. Robotics Integration

Robotics technology is transforming industries by adding speed, accuracy, and flexibility to automated processes. Whether it’s assembly, packaging, or material handling, Pulse Control’s robotic solutions ensure that your operations run smoothly and efficiently, all while reducing the need for manual labor.

5. Energy Management Solutions

Energy consumption is one of the largest expenses for industrial businesses. Pulse Control’s energy management solutions help monitor and optimize energy use across your facility, leading to significant cost savings and enhanced sustainability.

Applications of Industrial Automation: Transforming Industries for the Future

Industrial automation is one of the most transformative technological advancements of the modern age. By integrating systems like robots, artificial intelligence (AI), machine learning (ML), programmable logic controllers (PLCs), and data analytics into manufacturing and production processes, automation is revolutionizing how industries operate. The applications of industrial automation are vast and touch almost every aspect of the manufacturing, energy, logistics, and service sectors. From enhancing productivity to improving safety and quality control, automation offers numerous benefits that enable industries to stay competitive in a fast-changing global economy.

1. Manufacturing and Assembly Lines

One of the most significant applications of industrial automation is in manufacturing and assembly lines. Automation technologies have drastically improved the speed, accuracy, and consistency of production processes.

Key Areas of Automation in Manufacturing:

Robotics: Robots are widely used for tasks such as assembly, welding, painting, and material handling. They can operate 24/7, which increases production rates and reduces labor costs. With advancements in AI, robots can now adapt to changes in the production environment, making them more flexible and efficient.

Automated Guided Vehicles (AGVs): These are used for transporting materials and products throughout a facility without human intervention. AGVs can navigate through predefined paths, reducing the need for manual labor in material handling and enhancing operational efficiency.

CNC Machines and 3D Printing: Computer Numerical Control (CNC) machines are automated devices that follow precise instructions to perform tasks such as cutting, milling, and drilling. Similarly, 3D printing (additive manufacturing) is used for creating highly customized parts and prototypes, automating the production process while allowing for greater flexibility.

Packaging: Automated systems are used in packaging products at the end of the production line. These systems can package items at high speed and with greater consistency, reducing the chances of errors or damage that might occur with manual packaging.

Quality Control: Automated vision systems are deployed to detect defects in manufactured products. These systems use cameras and sensors to check for discrepancies in real time, ensuring only products that meet high-quality standards make it to the final stage of production.

2. Automotive Industry

The automotive industry is a prime example of how industrial automation can be applied to improve efficiency, safety, and innovation. Automation has been at the heart of automotive production for decades, with major advancements occurring in recent years.

Key Areas of Automation in the Automotive Industry:

Assembly Line Robotics: Robots are used extensively in automotive manufacturing to perform tasks such as welding, painting, assembly, and testing. These robots work with incredible precision, reducing the chances of human error and speeding up production times.

Automated Paint Systems: Automated paint spraying robots are used to apply coatings to car bodies in a consistent and precise manner, ensuring a high-quality finish while reducing paint waste and improving safety by reducing workers’ exposure to chemicals.

Quality Testing and Inspections: Automation is used in the quality control phase of automotive production, where robots and AI-powered systems are employed to test vehicle components and perform inspections for defects. Automated systems can inspect parts for dimensional accuracy, finish quality, and other critical parameters.

3. Food and Beverage Industry

The food and beverage industry has embraced automation to improve production efficiency, ensure food safety, and meet increasing consumer demand. Automation in this industry is particularly beneficial because it helps maintain strict hygiene standards while optimizing production.

Key Areas of Automation in Food and Beverage:

Processing and Packaging: Automated systems are used to sort, process, and package food products. This includes the automation of tasks like slicing, mixing, baking, and packaging, ensuring high-speed processing while maintaining food safety standards. For instance, automated packaging machines can seal, label, and box products with minimal human intervention.

Pasteurization: In food production, pasteurization is a critical process to eliminate harmful bacteria. Automated pasteurization systems allow for precise control of temperature and time, improving efficiency while maintaining product safety.

Sorting and Quality Control: Automated vision systems and sensors are used to sort food items based on size, color, and quality. These systems can detect imperfections like bruising or contamination, ensuring that only the best products reach the consumer.

Inventory Management: Automation also plays a key role in managing inventory. RFID and barcode scanning systems are used to track goods from production to distribution, ensuring that stock levels are optimized, and traceability is maintained.

4. Pharmaceutical Industry

The pharmaceutical industry relies on automation for everything from manufacturing and packaging to quality control and compliance with regulatory standards. Given the high stakes involved in drug production, precision and efficiency are critical.

Key Areas of Automation in Pharmaceuticals:

Production and Manufacturing: Automated systems are used for the high-precision formulation and packaging of pharmaceutical products. For example, tablet presses, capsule fillers, and liquid fillers are automated to ensure accurate dosages and consistent product quality.

Packaging: Automated systems are used to label, bottle, and package drugs. Automation ensures that products are sealed, labeled, and packaged according to regulatory guidelines, which helps prevent errors in product packaging that could lead to serious health risks.

Batch Production and Control: Automation helps ensure consistency during batch production, reducing human error and improving efficiency. Automated systems monitor parameters like temperature, pressure, and chemical composition during the production of pharmaceutical products.

Compliance and Traceability: Automation aids pharmaceutical companies in adhering to strict regulatory standards by providing traceability and real-time monitoring. Automated systems also record production data that can be easily accessed for audits and regulatory checks.

5. Energy Sector

Automation in the energy sector is transforming how energy is generated, distributed, and consumed. It helps improve the efficiency of energy production while supporting the move towards cleaner and more sustainable energy sources.

Key Areas of Automation in the Energy Sector:

Power Generation: Automation is used in power plants to optimize the production of electricity. From coal and gas to renewable sources like wind and solar, automated control systems monitor and regulate the various components of power plants, ensuring they operate at peak efficiency.

Energy Distribution: Automation helps optimize the distribution of energy to homes and businesses. Smart grids use real-time data to manage the flow of electricity and detect faults, reducing downtime and improving energy efficiency.

Renewable Energy: In renewable energy systems, such as wind farms and solar plants, automation plays a key role in monitoring energy production, tracking performance, and adjusting systems for optimal output.

6. Logistics and Warehousing

Automation in logistics and warehousing is transforming supply chain management by increasing the speed and accuracy of operations. With e-commerce demand skyrocketing, automation ensures faster and more reliable order fulfillment.

Key Areas of Automation in Logistics:

Automated Warehouses: Automated systems like conveyor belts, robotic arms, and automated guided vehicles (AGVs) are used to move products through the warehouse, sort items, and prepare orders for shipment. These systems reduce labor costs and increase operational efficiency.

Inventory Tracking: Automation in inventory management ensures accurate tracking of products in the warehouse. RFID and barcode scanning systems provide real-time updates on stock levels, helping companies maintain an optimal inventory.

Order Fulfillment: Automation helps speed up the order fulfillment process. Robots can retrieve products from shelves, pack them, and prepare them for shipping with minimal human intervention, ensuring fast and accurate delivery.

The applications of industrial automation are vast and growing as industries embrace new technologies to improve efficiency, reduce costs, and stay competitive. From manufacturing and automotive production to food processing, pharmaceuticals, energy, and logistics, automation is becoming a vital part of modern industry. With continued advancements in AI, robotics, and machine learning, the role of automation will only expand, offering even greater opportunities for businesses to enhance their operations and meet the demands of a dynamic global marketplace.

At Pulse Control, we specialize in providing comprehensive industrial automation solutions that help businesses streamline their operations, reduce waste, improve quality, and drive growth. Contact us today to learn how automation can transform your business and position you for success in the future.