Autonics

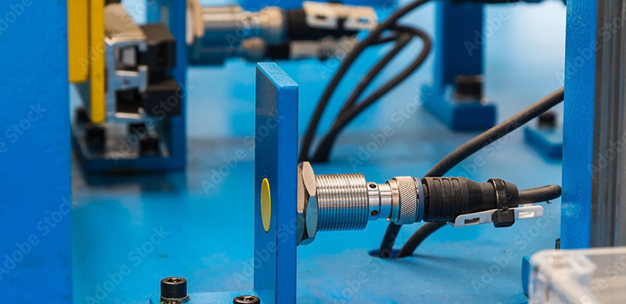

At pulse control , specializes in providing sensors that generate and monitor pulse signals for control and measurement applications. These sensors, such as flow sensors, rotary encoders, and proximity sensors, are used to track movement, speed, or fluid flow by converting physical actions into electrical pulse signals. The company supports industries like automation, oil and gas, manufacturing, and utilities, offering high-precision solutions for equipment monitoring, process control, and system feedback.

Design and Manufacture of Sensors: Pulse control systems may develop and produce specialized sensors that are essential for monitoring various parameters like pressure, temperature, flow, and position in control systems. These sensors are designed to be highly responsive to the demands of pulse-based regulation, ensuring accurate and efficient feedback.

Customization: As a supplier, pulse control systems may offer custom sensors tailored to the specific needs of their clients. They can design sensors that are built to integrate seamlessly with existing pulse control systems, considering factors like size, sensitivity, and operational conditions.

Integration with Pulse Control Technology: Pulse control suppliers ensure that the sensors they offer are fully compatible with pulse control mechanisms. They provide integrated solutions where sensors continuously monitor variables, and pulse controllers adjust the timing and power of pulses to achieve the desired outcomes.

Technology and Innovation: As suppliers, pulse control systems would also be at the forefront of sensor technology, developing innovative sensors that offer higher precision, faster response times, and greater durability. This helps enhance the overall performance of pulse control systems, offering superior control over the processes.

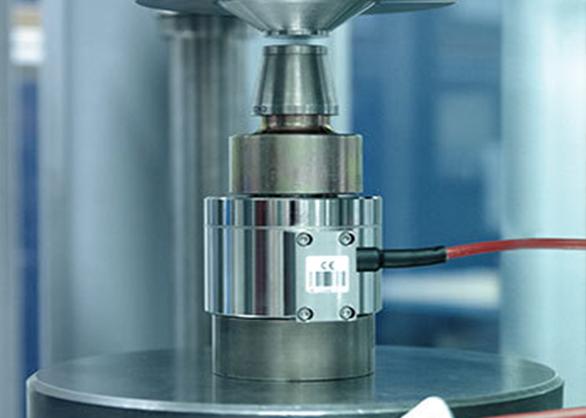

Testing and Calibration: These suppliers would conduct rigorous testing and calibration on their sensors before delivery to ensure accuracy, reliability, and long-term performance. Properly calibrated sensors are critical in pulse control systems to ensure the pulses are adjusted according to real-time data.

Ongoing Support and Maintenance: Pulse control systems, acting as suppliers, would also offer after-sales services, including technical support, maintenance, and replacement of sensors. This ensures continuous functionality and minimal downtime for their clients’ pulse control systems.

Compliance and Quality Assurance: As sensor suppliers, pulse control companies would focus on ensuring that their sensors meet relevant industry standards and regulations. They may also provide certifications of quality and safety for the sensors they supply, which are crucial in sensitive environments like industrial automation or medical devices.

pulse control systems as suppliers of sensors are involved in providing tailored, high-performance sensors that are integral to pulse control applications. Their role extends beyond merely supplying products to offering complete solutions, from sensor design and integration to testing, support, and compliance.