Scada

SCADA (Supervisory Control and Data Acquisition) is a system used for monitoring and controlling industrial processes and infrastructure. It is a vital component in various sectors, including manufacturing, energy, water management, and transportation. systems provide a comprehensive solution for data collection, analysis, and real-time control, enhancing operational efficiency and safety.

Here’s a detailed overview of systems, including their components, functionality, and applications:

1. Components of Systems

systems typically consist of several key components:

Human-Machine Interface (HMI): The HMI provides a visual representation of the industrial process, allowing operators to monitor and control operations. It displays real-time data through graphical interfaces, dashboards, and alerts, enabling quick decision-making.

Supervisory System: This component collects data from various field devices, processes it, and communicates with the HMI. The supervisory system manages data logging, event handling, and system control.

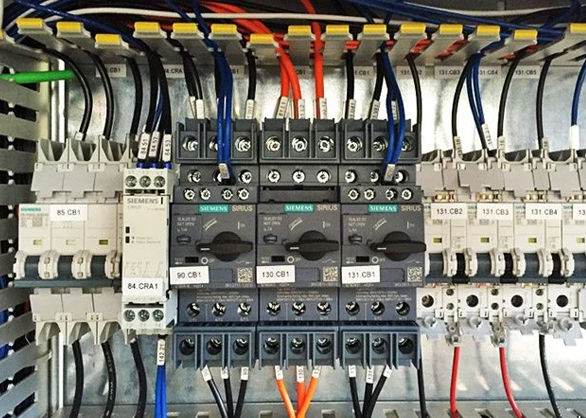

Field Devices: These include sensors, actuators, and other devices that collect data from the physical process. Sensors measure parameters such as temperature, pressure, flow rate, and more, while actuators perform actions based on commands from the supervisory system.

Communication Infrastructure: systems rely on robust communication networks (wired or wireless) to transmit data between the field devices and the supervisory system. This infrastructure ensures reliable data exchange and remote access to the system.

Data Historian: A data historian stores historical data collected from field devices, allowing for trend analysis, reporting, and long-term data retention. This data can be used for performance evaluation and process optimization.

2. Functionality of Systems

systems perform various functions critical to effective industrial operations:

Real-time Monitoring: enables continuous monitoring of processes, providing operators with real-time insights into system performance. This allows for prompt identification of issues and timely intervention.

Data Acquisition: systems gather data from multiple sources, enabling operators to track performance metrics and key performance indicators (KPIs). The ability to access historical data helps in analyzing trends and improving decision-making.

Control Operations: allows operators to control equipment and processes remotely.

They can send commands to field devices, such as starting or stopping machinery, adjusting setpoints, and implementing safety measures.

Alarm Management: systems can generate alarms and notifications based on predefined thresholds or abnormal conditions. This feature helps operators respond quickly to potential issues, enhancing safety and reliability.

Reporting and Analysis: systems can generate reports on system performance, production statistics, and maintenance activities. Analyzing this data helps organizations identify areas for improvement and optimize operations.

3. Applications of Systems

systems are widely used across various industries:

Manufacturing: In manufacturing environments, systems monitor production lines, track equipment perform

ance, and optimize resource utilization. They help identify bottlenecks and improve overall efficiency.

Energy Management: is essential in the energy sector for managing power generation, transmission, and distribution. It enables utilities to monitor grid performance, manage load demands, and ensure reliable power supply.

Water and Wastewater Management: systems are used to monitor and control water treatment plants, distribution networks, and wastewater facilities. They help optimize water quality, manage flow rates, and ensure compliance with environmental regulations.

Transportation: In transportation systems, SCADA is employed to monitor traffic flow, manage public transportation systems, and ensure safety in rail and road networks. It aids in optimizing routes and improving response times during emergencies.

Building Management: systems are also used in building automation to monitor HVAC systems, lighting, and security. They help maintain optimal conditions while reducing energy consumption.

4. Benefits of Systems

systems offer numerous advantages, including:

Improved Efficiency: By providing real-time data and control capabilities, systems enhance operational efficiency and reduce downtime.

Increased Safety: SCADA systems improve safety by allowing for immediate response to alarms and abnormal conditions, reducing the risk of accidents.

Cost Savings: By optimizing processes and resource utilization, systems can lead to significant cost savings over time.

Data-Driven Decision Making: Access to historical and real-time data allows organizations to make informed decisions based on actual performance metrics.

Conclusion

In summary, systems are crucial for modern industrial operations, enabling organizations to monitor and control processes efficiently. With their ability to collect and analyze data in real-time, systems enhance productivity, safety, and decision-making across various sectors. As technology continues to evolve, systems are also adapting to incorporate advancements such as cloud computing, the Internet of Things (IoT), and cybersecurity measures, further enhancing their capabilities and importance in industrial automation.

Here are some current trends in (Supervisory Control and Data Acquisition) systems:

1. Integration with IoT (Internet of Things)

The integration of systems with IoT devices is transforming industrial automation. IoT sensors provide real-time data that enhances monitoring and control capabilities. This trend allows for better data collection and analysis, enabling organizations to make more informed decisions and optimize operations. With the rise of IoT, systems can leverage vast amounts of data from connected devices, leading to improved efficiency and predictive maintenance.

2. Cloud-Based Solutions

Many organizations are moving towards cloud-based systems to enhance scalability, flexibility, and accessibility. Cloud solutions reduce the need for on-premises hardware and offer the ability to access applications from anywhere with an internet connection. This trend allows for better data storage, collaboration, and integration with other cloud-based tools, facilitating data-driven decision-making across teams and locations.

3. Enhanced Data Analytics and AI

Advanced data analytics and artificial intelligence (AI) are increasingly being integrated into systems. These technologies enable predictive analytics, which helps organizations anticipate potential failures and optimize performance. By analyzing historical data and identifying patterns, AI can enhance decision-making processes and improve operational efficiency, ultimately reducing costs and downtime.

4. Cybersecurity Focus

With the growing connectivity of SCADA systems, cybersecurity has become a significant concern. Organizations are increasingly prioritizing cybersecurity measures to protect their SCADA networks from cyber threats.

This includes implementing advanced security protocols, conducting regular vulnerability assessments, and using encryption to safeguard data transmission. Regulatory compliance and the need to protect sensitive data are driving this trend.

5. Mobile Access and Remote Monitoring

The demand for mobile access to systems is on the rise, allowing operators to monitor and control processes from smartphones and tablets. This trend enhances flexibility, enabling real-time decision-making and rapid response to alarms or anomalies. Remote monitoring capabilities are particularly valuable in industries with multiple locations or in remote environments where on-site personnel may be limited.

6. Interoperability and Standardization

As industries adopt diverse automation technologies, interoperability among different systems is becoming increasingly important. Organizations are looking for solutions that can seamlessly integrate with existing infrastructure, protocols

, and devices. Industry standards such as OPC UA (Open Platform Communications Unified Architecture) are gaining traction to facilitate communication between different systems and improve data exchange.

7. Visualization and User Experience Enhancements

There is a growing emphasis on improving the user experience of systems through enhanced visualization and user interfaces. Modern applications are focusing on providing intuitive dashboards, advanced graphical representations, and customizable views that help operators quickly understand system status and performance. Improved visualization aids in better decision-making and enhances operator efficiency.

8. Decentralized Control Systems

Decentralized

systems are gaining popularity, allowing for localized control of processes rather than relying solely on a centralized system. This trend enhances reliability, reduces latency, and improves resilience against network disruptions. Decentralized systems can operate independently in critical situations, providing better control and safety.

Conclusion

These trends reflect the ongoing evolution of systems in response to advancements in technology and the increasing demands of industries. By adopting these trends, organizations can enhance operational efficiency, improve decision-making, and ensure the security of their environments. As the industrial landscape continues to change, systems will play a vital role in supporting the automation and monitoring of complex processes across various sectors.

The importance of (Supervisory Control and Data Acquisition) systems in modern industrial operations cannot be overstated. They play a crucial role in enhancing efficiency, safety, and decision-making across various sectors. Here’s an in-depth look at the significance of systems:

1. Real-Time Monitoring and Control

systems provide real-time visibility into industrial processes, allowing operators to monitor various parameters such as temperature, pressure, flow rates, and system performance. This immediate access to data enables quick decision-making and the ability to respond promptly to anomalies or operational issues, thus preventing potential failures or accidents.

2. Increased Efficiency and Productivity

By automating data collection and control processes, SCADA systems enhance operational efficiency. They streamline workflows, reduce manual intervention, and optimize resource utilization. This leads to increased productivity as operators can focus on more strategic tasks rather than routine monitoring.

3. Data-Driven Decision Making

systems collect and analyze large volumes of data, providing valuable insights into system performance. Historical data can be used for trend analysis and performance evaluation, enabling organizations to make informed decisions based on actual metrics. This data-driven approach fosters continuous improvement and helps identify areas for optimization.

4. Enhanced Safety and Risk Management

Safety is a top priority in industrial environments, and systems contribute significantly to risk management.

By providing real-time monitoring and alarm management, SCADA helps operators identify hazardous conditions and respond swiftly to mitigate risks. This capability is essential in sectors like energy, manufacturing, and water management, where safety is critical.

5. Improved Communication and Collaboration

systems facilitate better communication among various teams and departments. With centralized data access, stakeholders can collaborate more effectively, sharing insights and coordinating efforts. This improved communication leads to a more integrated approach to operations, enhancing overall organizational performance.

6. Cost Savings and Resource Optimization

By optimizing processes and reducing downtime, systems contribute to significant cost savings. Organizations can minimize operational costs through efficient resource management, predictive maintenance, and reduced energy consumption. The ability to identify inefficiencies and implement corrective actions further enhances cost-effectiveness.

7. Scalability and Flexibility

Modern systems are designed to be scalable, accommodating the growth of industrial operations. Organizations can expand their SCADA infrastructure as needed, integrating

new devices and technologies without major overhauls. This flexibility ensures that systems can evolve alongside business needs and technological advancements.

8. Regulatory Compliance

In many industries, compliance with regulatory standards is essential. SCADA systems facilitate compliance by providing accurate data logging, reporting, and documentation. This capability ensures that organizations meet industry regulations and environmental standards, minimizing the risk of penalties or legal issues.

9. Integration with Other Systems

systems can integrate seamlessly with other industrial automation technologies, such as PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), and MES (Manufacturing Execution Systems). This integration enhances overall operational efficiency, allowing for coordinated control and data exchange between systems.

Conclusion

In conclusion, systems are a cornerstone of modern industrial automation, offering numerous benefits that enhance efficiency, safety, and decision-making. As industries continue to evolve and embrace digital transformation, the role ofwill become increasingly vital in supporting complex processes, optimizing resources, and ensuring safe and efficient operations. Organizations that invest in robust solutions position themselves to thrive in a competitive landscape, leveraging real-time data to drive innovation and continuous improvement.

Emerging trends in (Supervisory Control and Data Acquisition) systems reflect advancements in technology, changing industrial needs, and a shift towards more efficient, secure, and integrated operations. Here are some of the key emerging trends in SCADA:

1. Artificial Intelligence (AI) and Machine Learning (ML)

The integration of AI and ML into SCADA systems is gaining traction, enabling predictive analytics and intelligent decision-making. These technologies help identify patterns and anomalies in data, allowing for predictive maintenance, real-time optimization of processes, and enhanced decision support. AI-driven algorithms can forecast equipment failures and recommend proactive measures, reducing downtime and operational costs.

2. Edge Computing

Edge computing is becoming increasingly relevant in systems. Instead of sending all data to a central server or cloud, data processing occurs closer to the data source, reducing latency and bandwidth usage. This trend allows for faster response times and real-time decision-making, particularly in environments where immediate action is crucial. Edge devices can perform initial data analysis and only send relevant information to the central system, optimizing data flow and efficiency.

3. Cybersecurity Enhancements

As SCADA systems become more interconnected, cybersecurity is a top priority. Emerging trends include the adoption of advanced security protocols, AI-driven threat detection, and continuous monitoring for vulnerabilities. Organizations are investing in cybersecurity frameworks to protect SCADA networks from cyber threats, ensuring data integrity and system reliability. Regular security audits, employee training, and incident response plans are also becoming standard practices.

4. Cloud and Hybrid Solutions

Cloud-based solutions are on the rise, offering greater scalability, flexibility, and cost-effectiveness.

Organizations can store large amounts of data in the cloud and access SCADA applications remotely. Hybrid models, combining on-premises and cloud resources, are also emerging, allowing organizations to leverage the benefits of both approaches while maintaining critical data locally.

5. Interoperability and Standardization

The push for interoperability among different systems and devices is becoming increasingly important. Organizations are seeking solutions that can seamlessly integrate with existing infrastructure, protocols, and technologies. Standards such as OPC UA (Open Platform Communications Unified Architecture) facilitate communication between diverse systems, enabling data exchange and collaboration across platforms.

6. Enhanced Visualization and User Experience

Modern systems are focusing on improving user interfaces and visualization capabilities. Intuitive dashboards, advanced graphical representations, and customizable views help operators quickly understand system performance and identify issues. Enhanced visualization tools enable better decision-making by presenting complex data in a more digestible format, facilitating easier monitoring and control.

7. Decentralized Architectures

Decentralized SCADA architectures are emerging as a response to the need for greater reliability and resilience. In these systems, control functions are distributed across multiple nodes rather than relying solely on a central controller. This decentralization enhances system robustness, allowing for continued operation even if parts of the network experience issues.

8. Integration with IoT and Smart Devices

The convergence of and IoT technologies is a significant trend, allowing for enhanced data collection and monitoring capabilities. IoT devices can provide real-time data from various sources, which systems can analyze and utilize for improved decision-making. This integration enables smarter operations, remote monitoring, and better resource management.

9. Data Analytics and Business Intelligence

There is a growing emphasis on adv

anced data analytics and business intelligence within SCADA systems. Organizations are leveraging data to gain insights into operational performance, identify trends, and make strategic decisions. By incorporating analytics tools, SCADA systems can transform raw data into actionable insights, driving continuous improvement and operational excellence.

10. Sustainability and Energy Management

As industries focus on sustainability, systems are evolving to support energy management and resource optimization. can monitor energy consumption, identify inefficiencies, and suggest improvements to reduce waste. This trend aligns with broader sustainability goals and helps organizations lower their environmental impact while improving cost efficiency.

Conclusion

These emerging trends in SCADA systems demonstrate the ongoing evolution of industrial automation and the increasing importance of real-time data, advanced technologies, and cybersecurity. Organizations that embrace these trends will enhance their operational efficiency, improve decision-making, and position themselves competitively in a rapidly changing industrial landscape. As technology continues to advance, SCADA systems will play a crucial role in supporting smart, connected, and resilient industrial operations.

In the context of (Supervisory Control and Data Acquisition) systems, usually refers to "Substation Configuration Description," which is a standard file format used primarily in electrical substations. However, if you're looking for different types of systems or components, here's a comprehensive overview:

1. CentralizedSystems

Description: These systems have a single central server that collects and processes data from various remote devices and sites.

Use Cases: Common in industries where all operations can be managed from one location, such as power generation plants and manufacturing facilities.

2. Distributed SCADA Systems

Description: In this architecture, control and monitoring are distributed across multiple locations or nodes, allowing for localized processing of data.

Use Cases: Suitable for large-scale operations, such as oil and gas pipelines or water distribution networks, where different regions need to operate independently yet communicate with a central system.

3. Hybrid Systems

Description: Combines elements of both centralized and distributed SCADA systems. Some processes are managed centrally, while others are handled locally.

Use Cases: Useful in complex operations where different units require varying levels of control and monitoring, such as large industrial complexes.

4. Cloud-Based Systems

Description: Utilize cloud technology for data storage and processing. These systems offer flexibility, scalability, and remote access.

Use Cases: Ideal for organizations looking to minimize hardware costs and enhance data accessibility, such as smart cities and distributed energy resources.

5. Web-Based SCADA Systems

Description: Accessible through web browsers, these systems allow users to monitor and control processes remotely via the internet.

Use Cases: Often used in industries where remote access is critical, such as agriculture, where operators may monitor equipment from various locations.

6. Wireless Systems

Description: Use wireless communication technologies to connect remote devices to the system, reducing the need for physical cabling.

Use Cases: Suitable for applications in remote or difficult-to-access locations, like environmental monitoring or offshore oil rigs.

7. Mobile Systems

Description: Provide operators with mobile access to systems via smartphones or tablets, enabling real-time monitoring and control.

Use Cases: Useful for operators who need to be on the move, such as field technicians in utilities or manufacturing.

8. Industrial Systems

Description: Focused on specific industrial applications, these systems are designed to manage operations in sectors like manufacturing, oil and gas, and water treatment.

Use Cases: Tailored solutions for specific industries, incorporating industry-specific protocols and compliance requirements.

9. Process SCADA Systems

Description: Primarily used in process industries, these systems manage continuous production processes, like chemical manufacturing and food processing.

Use Cases: Essential for industries where processes are continuous and require precise monitoring and control.

10. Telecommunication Systems

Description: Designed to monitor and control telecommunications networks, including data transmission and network infrastructure.

Use Cases: Employed by telecommunications companies to ensure reliable and efficient network operations.

Conclusion

Each type of system serves specific needs and applications, reflecting the diverse requirements of various industries. As technology continues to advance, systems are becoming more integrated with IoT, cloud solutions, and advanced analytics, enhancing their capabilities and effectiveness in managing complex industrial processes. Understanding these types helps organizations choose the right SCADA solution to meet their operational goals.