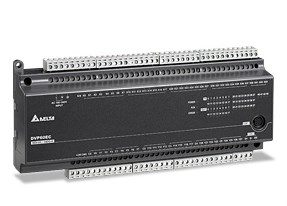

Delta

Omron

Mitsthubishi

Siemens

Veichi

Eaton

PLC-Programmable Logic Controller

Introduction to PLC (Programmable Logic Controller)

A Programmable Logic Controller (PLC) is an industrial digital computer designed to control manufacturing processes or machinery. Unlike regular computers, PLCs are built to operate in harsh environments, such as factories, where conditions like dust, extreme temperatures, and vibrations are common. They are used to automate systems, ensuring that tasks like assembly lines, machinery functions, and production processes are carried out with precision and reliability.

How PLCs Work

At the core, PLCs operate by receiving input signals from sensors or manual switches, processing this information through a pre-programmed set of instructions, and then triggering outputs that control machinery or systems. These inputs could be anything from temperature readings to the position of a machine. The PLC processes these inputs and sends commands to actuators, motors, valves, or other devices, ensuring smooth operation of industrial processes.

A PLC program is typically written using ladder logic or function block diagrams, which are easy to understand and visualize for engineers. Once programmed, the PLC continuously monitors its inputs and executes the instructions to maintain efficient control of the entire system.

Benefits of PLCs

One of the major advantages of PLCs is their flexibility. Unlike traditional mechanical control systems that require extensive rewiring for changes, a PLC can be easily reprogrammed to adapt to new functions or processes. This makes them highly cost-effective for industries looking to upgrade or modify production lines without massive overhauls.

Another significant benefit is reliability. PLCs are designed to run continuously and efficiently, even in challenging conditions, with minimal downtime. This reliability is crucial for industries that depend on continuous production, such as automotive, chemical processing, and manufacturing.

Applications of PLCs

PLCs are used in a wide range of industries. In the automotive industry, they control robotic arms in assembly lines to ensure the precise manufacture of parts. In food and beverage processing, PLCs regulate packaging machines, conveyor belts, and mixers. In energy production, they manage everything from power plant operations to water treatment facilities.

PLCs are also instrumental in building automation systems, controlling elevators, lighting, and HVAC (heating, ventilation, and air conditioning) systems in commercial buildings. Their ability to handle multiple inputs and outputs simultaneously makes them ideal for complex, large-scale operations.

Conclusion

Programmable Logic Controllers (PLCs) have revolutionized industrial automation by providing a flexible, reliable, and efficient method for controlling complex processes. Their ease of programming, robustness in harsh environments, and adaptability to various industrial applications make them essential tools in modern manufacturing and process automation. As industries continue to evolve and adopt new technologies, PLCs will remain at the heart of efficient and scalable automation systems.

Here are some common myths about Programmable Logic Controllers (PLCs) and the facts that debunk them:

1. Myth: PLCs Are Obsolete with the Rise of Modern Technology

Fact: While new technologies like industrial PCs and IoT-based systems are gaining popularity, PLCs remain a cornerstone of industrial automation. They are continually evolving, with modern PLCs integrating advanced features like Ethernet communication, remote monitoring, and IoT capabilities. Their robustness and ability to operate in harsh environments still make them a top choice for many industries.

2. Myth: PLCs Are Too Complex for Small and Medium Enterprises (SMEs)

Fact: PLCs come in a range of sizes and capabilities. Small, cost-effective PLCs are designed for SMEs and simple automation tasks, making them accessible for all types of businesses. With user-friendly programming environments and modular designs, PLCs can be tailored to suit both small and large-scale industrial needs.

3. Myth: PLC Programming Is Only for Engineers

Fact: While PLC programming does require some technical knowledge, it isn’t limited to engineers alone. Many PLCs use intuitive programming languages like ladder logic, which is graphical and easy to learn. Training courses and resources are widely available, allowing technicians and plant operators to understand and modify basic PLC programs.

4. Myth: PLCs Are Expensive to Implement

Fact: The cost of PLCs has significantly decreased over the years, and they are now available at different price points to meet various budget requirements. Additionally, the long-term savings due to increased efficiency, reduced downtime, and flexibility in process changes often outweigh the initial investment in a PLC system.

5. Myth: PLCs Are Difficult to Upgrade

Fact: Modern PLCs are designed to be flexible and scalable. They can easily be upgraded with new modules or software updates without replacing the entire system. This makes them future-proof, as they can evolve with the industry's needs and technological advancements.

6. Myth: PLCs Cannot Handle Complex Operations

Fact: PLCs are specifically designed to handle complex operations and control systems. With advancements in technology, modern PLCs can manage highly sophisticated tasks, such as motion control, robotics, and integration with smart manufacturing systems. They can process large amounts of data in real time, making them suitable for even the most intricate automation processes.

7. Myth: PLCs Are Only for Factory Automation

Fact: While PLCs are widely used in factories, their application goes beyond manufacturing. They are used in various industries, such as building automation (HVAC systems), energy management (power plants), transportation (traffic control), and water treatment facilities. Their versatility makes them an essential tool in many sectors.

Conclusion

Despite some misconceptions, PLCs remain a crucial part of industrial automation. They are versatile, reliable, and constantly evolving to meet the demands of modern industries. Far from being outdated or complex, PLCs are accessible, scalable, and indispensable in today’s manufacturing and processing environments.

Disadvantages of Programmable Logic Controllers (PLCs)

While PLCs offer many benefits in industrial automation, there are also some limitations and challenges associated with their use. Here are some key disadvantages:

1. Initial Cost

High Setup Costs: Although PLCs are cost-effective in the long run, the initial investment for purchasing and installing a PLC system can be high, especially for small businesses. The costs include hardware, programming software, training, and sometimes additional components like sensors and actuators.

2. Complex Programming for Advanced Tasks

Steep Learning Curve: While basic PLC programming (like ladder logic) is relatively simple, more complex systems involving advanced programming languages or sophisticated control processes can be challenging. Companies may need to hire specialized programmers or invest in training to properly handle complex automation needs.

3. Limited Processing Power

Slower Compared to Computers: PLCs, although highly reliable, often have limited processing power compared to modern industrial PCs or other advanced automation solutions. This can be a drawback for industries requiring extensive data processing or complex algorithms, where higher computing power might be necessary.

4. Hardware Limitations

Fixed I/O Configuration: Some PLC models come with a fixed number of input/output (I/O) ports, which may limit expansion. To increase the number of I/O ports, companies may need to invest in additional modules or entirely new systems, leading to higher costs and increased complexity.

5. Maintenance and Downtime

Programming Issues: Debugging and maintaining a PLC program can be difficult if the system grows too complex or if the original programmers are unavailable. In case of malfunction, it may take time to troubleshoot the problem, leading to production downtime.

Component Wear: Although PLCs are designed for durability, the physical components (such as input and output relays) may wear out over time. This can result in equipment failure or the need for regular maintenance to prevent breakdowns.

6. Dependence on Manufacturer Support

Proprietary Systems: Many PLC systems are proprietary, meaning they depend heavily on the manufacturer’s hardware and software. This can create challenges when upgrading or integrating with third-party systems, and users may face long-term dependency on the original supplier for updates, support, or replacements.

7. Limited Scalability for Certain Applications

Not Ideal for Large-Scale Systems: While PLCs are suitable for medium and small-scale automation, they can be less efficient in very large or highly complex automation environments. For example, Distributed Control Systems (DCS) or advanced industrial computers may be better suited for controlling large-scale, continuous operations.

8. Environmental Sensitivity

Operating Conditions: While PLCs are designed for harsh industrial environments, extreme conditions such as excessive humidity, very high temperatures, or extreme dust levels can still affect their performance. Protective housing or additional maintenance might be necessary to ensure longevity.

Conclusion

PLCs provide an excellent solution for many automation tasks, but their limitations, such as high initial costs, complexity in programming, and hardware constraints, can pose challenges. Careful consideration of the system’s scale, complexity, and future needs is essential before implementing a PLC-based automation solution. In certain cases, other automation technologies like industrial PCs or Distributed Control Systems (DCS) might be more suitable.

Industrial automation refers to the use of control systems, such as computers, PLCs (Programmable Logic Controllers), robots, and other technologies, to automate industrial processes. The goal of industrial automation is to enhance efficiency, reliability, and precision while reducing human intervention in tasks like manufacturing, material handling, and packaging. It’s a key driver in modern manufacturing and production environments, leading to higher productivity, improved safety, and reduced operational costs.

Key Components of Industrial Automation

PLCs (Programmable Logic Controllers):

PLCs are digital computers used in industrial settings to control machinery and processes. They monitor inputs (from sensors, switches, etc.), process them according to a pre-set program, and trigger outputs (actuators, motors) to execute specific tasks.

SCADA (Supervisory Control and Data Acquisition):

SCADA systems allow operators to monitor and control industrial processes remotely. They gather data from sensors and machines in real time, providing insights into system performance, while enabling remote adjustments and control.

Robotics:

Industrial robots are used to perform repetitive or dangerous tasks with high precision, such as assembling parts, welding, or packaging products. Robotics can enhance productivity by operating continuously with consistent quality output.

HMI (Human-Machine Interface):

HMIs are user interfaces that allow operators to interact with machines and control systems. They provide visual representations of the system’s processes, allowing for manual control or troubleshooting if necessary.

Sensors and Actuators:

Sensors provide real-time data from the environment, such as temperature, pressure, or position, to the control systems. Actuators perform the actions, such as opening valves, moving motors, or starting pumps, based on the signals from the control system.

Variable Frequency Drives (VFDs):

VFDs are used to control the speed of electric motors by adjusting the frequency of the electrical supply. They are essential in energy-saving and process control applications, allowing smooth and precise speed regulation.

Communication Networks:

Automation systems rely on communication networks like Ethernet or fieldbus protocols to connect various devices (PLCs, sensors, HMIs) and ensure real-time data exchange across the system.

Benefits of Industrial Automation

Increased Productivity:

Automation systems operate continuously, leading to faster production cycles and increased output compared to manual labor.

Improved Quality and Consistency:

Automated processes reduce human error, ensuring consistent product quality and fewer defects.

Cost Efficiency:

Automation reduces labor costs and operational expenses, particularly in high-volume manufacturing. Additionally, technologies like VFDs save energy by optimizing motor performance.

Enhanced Safety:

By automating hazardous or repetitive tasks, automation reduces the need for human involvement in dangerous environments, improving worker safety.

Data-Driven Decision Making:

Real-time monitoring and data collection enable more informed decision-making, preventive maintenance, and optimized system performance.

Applications of Industrial Automation

Manufacturing: Assembly lines, robotic welding, packaging, and quality control.

Process Industries: Chemical plants, oil and gas refineries, and water treatment facilities.

Food and Beverage: Processing, bottling, and packaging operations.

Pharmaceutical: Automated drug manufacturing, labeling, and packaging.

Automotive: Robotic assembly, painting, and quality testing.

Conclusion

Industrial automation transforms the way industries operate by enhancing productivity, reducing operational costs, and improving overall efficiency. From robotics and PLCs to advanced control systems like SCADA, automation technologies continue to shape the future of manufacturing and production, driving innovation and growth across various sectors.

Types of Programmable Logic Controllers (PLCs) are classified based on their size, application, and functionality. Below are the primary types of PLCs commonly used in industrial automation:

1. Compact PLC

Overview: Also known as a fixed or integrated PLC, compact PLCs have a fixed number of inputs and outputs (I/O) and are typically used for small-scale applications.

Features:

Fixed I/O count

Suitable for simple automation tasks

Small physical footprint

Applications: Used in small automation systems like simple conveyor belt operations, small packaging lines, and basic machinery control.

Examples: Delta’s DVP-SS2 series, Siemens LOGO!, Allen-Bradley MicroLogix.

2. Modular PLC

Overview: Unlike compact PLCs, modular PLCs are customizable with multiple modules for different functionalities, including expandable I/O, communication, and processing power.

Features:

Modular architecture allows easy expansion and customization

Can integrate multiple I/O, networking, and special modules

Supports more complex automation tasks

Applications: Widely used in manufacturing plants, process industries, and large industrial machines that require a high degree of customization and scalability.

Examples: Delta’s DVP-SV, Allen-Bradley ControlLogix, Siemens S7-300.

3. Rack-Mounted PLC

Overview: These are large and highly flexible systems where multiple PLC modules (processor, power supply, I/O modules) are placed in a rack structure.

Features:

High scalability, supporting large I/O counts

Centralized control and easy module integration

Used for complex and large-scale automation systems

Applications: Ideal for large industrial processes, power plants, refineries, and automation systems requiring extensive control and data processing.

Examples: Delta’s AH500 series, Siemens S7-400, Allen-Bradley ControlLogix.

4. Soft PLC

Overview: Soft PLCs run on a general-purpose computer or industrial PC instead of dedicated PLC hardware. They use software to emulate PLC functionality.

Features:

Can be installed on standard PCs or servers

Flexibility in integrating with other systems (e.g., SCADA, DCS)

Suitable for high-level process control and data management

Applications: Often used in large-scale process automation, where integration with data analytics, visualization, or complex calculations is required.

Examples: Codesys-based Soft PLCs, Siemens WinAC, Rockwell Automation SoftLogix.

5. Safety PLC

Overview: Designed for applications requiring safety integrity, safety PLCs ensure reliable control in hazardous environments or where safety-critical functions are essential.

Features:

Dual-processor architecture for redundancy

Built-in safety protocols to prevent hazardous conditions

Certified to meet safety standards (e.g., IEC 61508, SIL levels)

Applications: Used in environments like oil and gas, chemical plants, machine safety systems, and critical manufacturing processes.

Examples: Siemens S7 Safety, Allen-Bradley GuardLogix, Mitsubishi MELSEC-F.

6. Distributed PLC

Overview: These systems consist of multiple PLC units distributed throughout a plant or factory, communicating with each other over a network for coordinated control.

Features:

Multiple small PLCs linked through a communication network

Allows control of different areas in large-scale systems

Reduces wiring complexity in distributed systems

Applications: Common in large-scale manufacturing systems, where control is needed across various sections of a plant or facility.

Examples: Siemens ET 200, Rockwell Automation CompactLogix.

7. Nano PLC

Overview: The smallest type of PLCs, nano PLCs are compact and inexpensive, designed for extremely simple automation tasks with limited I/O.

Features:

Very small size and fixed I/O

Cost-effective and user-friendly

Simple programming and operation

Applications: Used in small standalone machines, home automation, or simple device control.

Examples: Schneider Electric Zelio, Siemens LOGO!.

8. Redundant PLC

Overview: Redundant PLC systems are designed for critical applications where continuous operation is essential. They feature dual systems (primary and backup) that take over if one fails.

Features:

High availability with automatic failover

Dual power supplies, CPUs, and communication modules

Prevents downtime in mission-critical applications

Applications: Used in power plants, data centers, and industries where system failures would be catastrophic.

Examples: Delta’s AH500 with redundancy features, Allen-Bradley ControlLogix Redundancy.

Conclusion

The type of PLC selected depends on the scale and complexity of the automation task. Compact PLCs suit small applications, while modular and rack-mounted PLCs handle large-scale systems. Soft PLCs integrate with advanced IT systems, and safety and redundant PLCs provide security in critical environments. Understanding these types helps businesses choose the right PLC for their automation needs.