HMI-SCADA-PLC CONTROL SYSTEM services

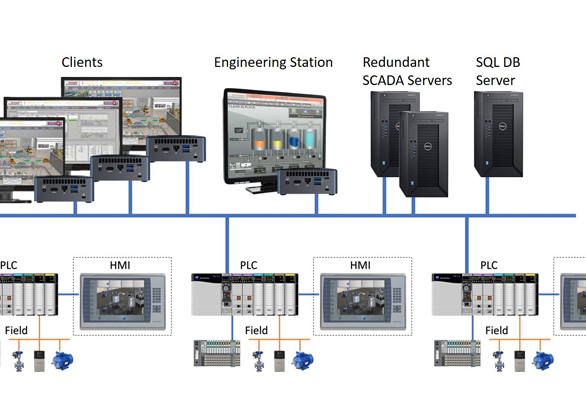

In an increasingly digital and interconnected world, automation and control systems have become essential tools for industries aiming to improve operational efficiency, safety, and data-driven decision-making. At the heart of this transformation is the seamless integration of Human-Machine Interface (HMI), Supervisory Control and Data Acquisition (SCADA), and Programmable Logic Controller (PLC) systems. These technologies work together to create a robust, highly effective control architecture, enabling real-time monitoring, data collection, and responsive control of critical industrial processes.

With automation demands on the rise, the role of HMI-SCADA-PLC systems has expanded across sectors like manufacturing, energy, water management, transportation, and beyond. By allowing centralized oversight and precision control, these systems reduce human error, enhance safety, and provide the agility needed to adapt to changing conditions instantly. The result is streamlined production, optimized resource management, and better compliance with regulatory standards.

This is where Pulse Control steps in. As a leader in HMI-SCADA-PLC integration, Pulse Control offers customized, scalable solutions to meet the unique demands of each industry. From initial assessment to system installation, programming, and ongoing support, our services are designed to empower organizations with powerful automation tools that drive productivity and sustainability. With Pulse Control’s commitment to quality and innovation, companies can rely on a partner dedicated to making their operations smarter, safer, and future-ready.

What Are HMI, SCADA, and PLC Control Systems?

- HMI (Human-Machine Interface): The interface that allows operators to interact with the control system, providing real-time data visualization and control functions.

- SCADA (Supervisory Control and Data Acquisition): A system used for monitoring and controlling industrial processes from a central location, offering oversight, data collection, and advanced analytics.

- PLC (Programmable Logic Controller): An industrial digital computer designed to manage and automate electromechanical processes with precision and reliability.

Together, these components create a powerful control architecture that can monitor and regulate everything from manufacturing processes to infrastructure management.

Benefits of HMI-SCADA-PLC Control Systems

- Enhanced Operational Efficiency: By enabling seamless interaction between HMI, SCADA, and PLC systems, operators gain better control over complex processes, improving efficiency.

- Real-Time Monitoring and Control: The combined system allows for continuous monitoring, quick responses to system changes, and immediate adjustments, reducing downtime and errors.

- Data-Driven Insights: SCADA collects and analyzes large amounts of data, empowering decision-makers with insights that drive operational improvements.

- Improved Safety and Compliance: Automation through PLCs reduces human error, ensuring safer operations and compliance with regulatory standards.

- Scalability and Flexibility: The system is easily adaptable, allowing industries to expand and modify controls as their needs grow.

Pulse Control’s expert team provides end-to-end services, from initial system design to full-scale implementation and support.

1. Customized Design and Engineering

At Pulse Control, we understand that every industrial setting has unique needs. Our design process begins with a thorough evaluation of the client’s requirements, environment, and desired outcomes. Using this information, we develop customized solutions that integrate seamlessly into the existing infrastructure, ensuring that the HMI-SCADA-PLC systems work harmoniously to support operational goals.

2. Installation and Configuration

Once the design is approved, our experienced technicians handle the installation and configuration. With expertise across multiple industry sectors, Pulse Control ensures that every system is set up for optimal functionality, reliability, and safety.

3. Programming and Integration

Programming and integration are critical for automation success. Our team configures each PLC for precise, error-free operation and integrates it with HMI and SCADA systems. This integration allows real-time communication and process control, enabling swift responses to changing conditions.

4. Testing and Validation

Before launch, Pulse Control rigorously tests the entire HMI-SCADA-PLC system to ensure it meets performance and safety standards. We conduct comprehensive tests and validate that all components are functioning correctly to prevent any unexpected issues.

5. Training and Support

After installation, Pulse Control offers in-depth training to operators, empowering them to utilize the system effectively. We provide ongoing technical support and maintenance services to keep systems performing at their best over time.

pulse Control’s HMI-SCADA-PLC solutions are versatile and adaptable, benefiting various industries:

- Manufacturing: Streamline production processes, improve quality control, and maximize productivity.

- Utilities: Monitor and control water, gas, and electricity distribution with accuracy.

- Oil and Gas: Ensure safe, efficient extraction and processing with robust monitoring and control.

- Transportation: Optimize infrastructure, including rail systems and traffic management.

- Agriculture: Automate irrigation and monitor crop health for sustainable farming practices.

By investing in Pulse Control’s HMI-SCADA-PLC Control System services, industries can unlock the potential of advanced automation to drive productivity, safety, and efficiency. Our customized solutions enable industries to operate smarter and more competitively in today’s dynamic landscape. With Pulse Control as your partner, you can be confident that your HMI-SCADA-PLC system will be optimized for success, ensuring seamless operation and growth in an increasingly automated world.