Control panels are essential in industrial and commercial systems as they house the necessary equipment to manage, monitor, and control various electrical and mechanical systems. The uses of control panels can be categorized into different types of applications, depending on their complexity and the type of system being managed. key uses of control panels:

1. Automation and Process Control

Control panels are central to automation systems, where they regulate and control processes in industries such as manufacturing, chemical, and food processing. They house components like Programmable Logic Controllers (PLCs), sensors, actuators, and other devices to automate tasks like:

- Conveyor belt speed regulation

- Material handling

- Temperature and pressure monitoring

- Level control in tanks

2. Electrical Distribution and Power Control

Control panels manage the distribution of electrical power across various systems. They ensure the efficient and safe operation of electrical circuits, providing functions such as:

- Circuit protection through fuses, circuit breakers, or overload relays

- Monitoring and controlling the electrical load

- Switching between different power sources (e.g., from grid power to backup generators)

3. HVAC (Heating, Ventilation, and Air Conditioning) Control

In buildings and large facilities, control panels are used to regulate HVAC systems. These panels help maintain optimal environmental conditions by controlling:

- Temperature

- Humidity

- Air quality

- Ventilation speeds

- Energy usage optimization

4. Motor Control

Control panels are used to control motors in various machinery. They can control motor speed, direction, and protection, including:

- Variable Frequency Drives (VFDs) to adjust motor speed

- Soft starters to reduce the inrush current when motors start

- Overload protection to prevent motor damage

- Motor start/stop control

5. Lighting Control

Control panels are used for managing lighting systems in both commercial and residential applications. They can control:

- On/off switching

- Dimming systems

- Automated lighting based on time of day or occupancy

- Emergency lighting systems in case of power failures

6. Safety and Alarm Systems

Control panels are critical in monitoring and managing safety systems. They allow operators to:

- Detect hazards such as gas leaks, fires, or temperature fluctuations

- Trigger alarms and shutdowns in case of malfunction or dangerous conditions

- Activate emergency systems, like fire suppression or cooling systems

7. Energy Management

Control panels are often used in energy management systems to monitor and control the consumption of energy. Functions include:

- Load shedding to optimize energy use during peak demand times

- Renewable energy integration (e.g., solar or wind) with the grid

- Real-time energy monitoring and data logging

- Automated switching between energy sources (e.g., grid, battery, or generator)

8. Water Treatment and Pump Control

In municipal water treatment or irrigation systems, control panels manage various pumps and valves to ensure optimal operation. These panels can:

- Control pump cycles to manage water flow

- Monitor water levels and pressure

- Control valve operations for directing water to appropriate locations

- Track chemical dosing for water treatment

9. Building Management Systems (BMS)

Control panels are used in building automation systems to monitor and control various aspects of a building’s operation, including:

- Lighting systems

- HVAC systems

- Access control and security systems

- Fire and smoke detection systems

10. Communication and Data Control

In some industries, control panels are equipped with communication systems that allow remote monitoring and data logging, helping operators make decisions based on real-time data. These include:

- Remote control and monitoring through SCADA (Supervisory Control and Data Acquisition) systems

- Data collection and analysis for performance optimization

- Alarm and notification systems for troubleshooting and maintenance

11. Industrial Equipment Control

In large industrial settings, control panels are used to operate specific pieces of equipment, including:

- Welding machines

- CNC (Computer Numerical Control) machines

- Robotic arms and automated assembly lines

- Packaging and sorting machines

12. Traffic Control and Transportation Systems

Control panels are used in traffic management systems to control:

- Traffic lights and signals

- Toll systems

- Railway signaling systems

- Airport or seaport monitoring systems

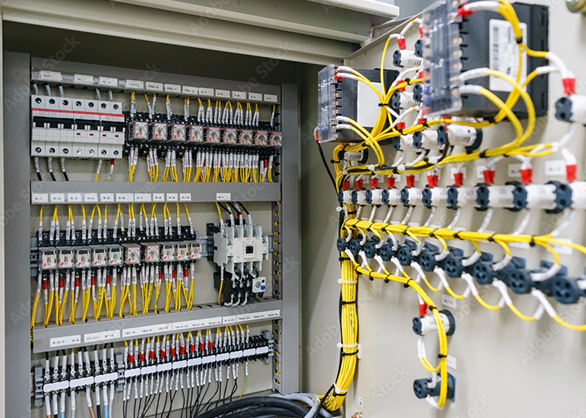

Key Components Found in Control Panels:

- Circuit breakers for overload protection

- Relays for switching and controlling signals

- Fuses for safety against electrical surges

- Transformers to step down voltage levels

- PLCs (Programmable Logic Controllers) for automation

- HMI (Human-Machine Interface) for user interaction

- Meters for monitoring electrical parameters (e.g., voltage, current)

Control panels play a vital role in the smooth operation of numerous systems across a wide range of industries. They not only provide the functionality needed for managing processes but also ensure safety, efficiency, and reliability of the operations they control.