Control Panel Designing services

In today’s world, industries are driven by the need for precision, efficiency, and automation. Whether it’s a factory, laboratory, or a commercial establishment, control panels are the heart of any automated system. These panels not only streamline operations but also provide real-time insights, ensuring the system runs smoothly and efficiently. When it comes to control panel design, Pulse Control stands out as a leader in the field, offering top-notch services that are tailored to meet the needs of diverse industries.

What Is Control Panel Design?

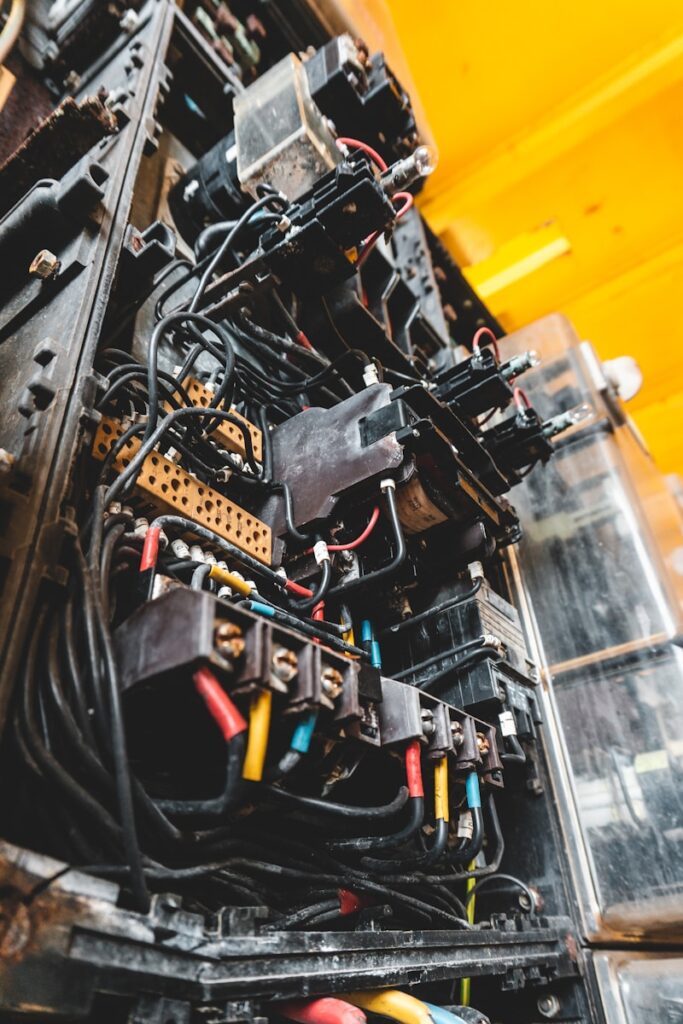

Control panels are the interface through which users interact with machines or automated systems. These panels house essential components like switches, relays, fuses, disconnects, and controllers, which help in regulating the operation of machinery, ensuring safety, and enhancing overall functionality. Control panel design involves selecting, arranging, and wiring these components into a compact, user-friendly interface that is both safe and efficient.

At Pulse Control, the focus is on creating control panels that not only fulfill the functional requirements but are also easy to operate, highly durable, and in line with international standards.

The Design Process at Pulse Control

The design process at Pulse Control is comprehensive and structured to ensure that each control panel meets the specific needs of the client while complying with all relevant standards. Here’s a look at the typical steps involved:

1. Initial Consultation and Requirement Analysis

Pulse Control begins by understanding the client’s needs, goals, and operational requirements. During this stage, engineers analyze the system specifications, assess the environment, and identify safety requirements to provide a customized solution.

2. Design and Engineering

Once the requirements are understood, Pulse Control’s design team works on the layout of the control panel. The design includes selecting components, creating electrical schematics, and deciding the best configuration. They use CAD software to create accurate drawings and simulations.

3. Panel Fabrication and Assembly

After finalizing the design, the control panel is fabricated using high-quality materials. Pulse Control’s expert technicians assemble all components carefully, ensuring that each part is wired and configured correctly.

4. Testing and Quality Control

Before the panel is dispatched or installed, it undergoes thorough testing to ensure that it meets the required specifications and performs reliably under real-world conditions. This includes functional testing, safety checks, and regulatory compliance.

5. Installation and Commissioning

Pulse Control doesn’t stop at just delivering the control panel; their team also handles the installation and commissioning of the system, ensuring everything is set up for optimal performance. They also provide training to ensure that the end users are familiar with the operation and maintenance of the system.

6. Ongoing Support and Maintenance

Pulse Control provides ongoing support and maintenance services to ensure the longevity and reliability of your control panel. Whether it’s routine maintenance or troubleshooting, their team is available to assist whenever needed.

Understanding the Role of Control Panels in Smart Building Automation

In the modern era, smart building automation systems are becoming increasingly popular as they offer significant advantages in terms of energy efficiency, security, comfort, and cost savings. At the heart of these advanced systems lies the control panel, a crucial component that enables centralized management of a building’s various systems. Control panels act as the interface between the building’s physical systems—such as heating, ventilation, air conditioning (HVAC), lighting, and security—and the operator who manages these systems. By seamlessly integrating these components into a unified system, control panels empower smart buildings to function more efficiently and adapt to the needs of their occupants.

Centralized Control and Integration

A smart building typically integrates various subsystems such as HVAC, lighting, energy management, fire alarms, and security systems into a single network. Control panels play a vital role in bringing these subsystems together, allowing them to communicate and function as a cohesive unit. With control panels, operators can monitor and manage different systems from a single, centralized location. For instance, by adjusting HVAC settings via the control panel, the building’s temperature can be optimized to improve comfort while reducing energy consumption. Similarly, the lighting system can be automated to adjust based on occupancy or time of day, contributing to overall energy savings.

Real-Time Monitoring and Diagnostics

One of the key features of control panels in smart building automation is their ability to provide real-time monitoring and diagnostics. These panels allow operators to track the performance of different subsystems, identifying potential issues before they escalate into costly problems. Control panels are often equipped with sensors and feedback mechanisms that allow them to collect data from various building systems. This data is then analyzed to provide actionable insights, such as identifying areas where energy consumption can be reduced or detecting maintenance needs. Early detection of system faults can minimize downtime, enhance safety, and improve the overall performance of the building.

Energy Management and Sustainability

Control panels are integral to achieving energy management goals in smart buildings. They enable automated energy-saving features like dimming lights when natural light is sufficient, or controlling heating and cooling based on real-time occupancy data. By collecting data on the building’s energy usage, control panels help identify inefficiencies, enabling managers to adjust system settings to optimize energy consumption. This not only leads to lower operational costs but also supports the building’s sustainability objectives by reducing its overall carbon footprint. Many modern control panels even integrate with building Energy Management Systems (EMS), which help monitor and control energy use across multiple buildings or facilities.

User Experience and Comfort

For occupants of smart buildings, control panels also enhance user experience and comfort. Through smart technology, control panels adjust the building environment based on occupancy patterns or personal preferences. For example, smart thermostats connected to a control panel can adjust room temperatures for optimal comfort while reducing unnecessary heating or cooling in unoccupied rooms. Additionally, lighting can be tailored to suit occupant needs, with automated dimming or color changes based on the time of day or individual preferences. Some advanced control panels even allow occupants to customize their environment through mobile apps or voice commands, making it easier for them to manage their surroundings without manual adjustments.

Security and Safety Systems

Control panels also play a crucial role in maintaining security and safety in smart buildings. They integrate with security systems like access control, surveillance cameras, and alarm systems to ensure the safety of the building and its occupants. For example, a control panel can manage the building’s security cameras, allowing operators to view live feeds, record footage, and even control camera positioning. In the event of an emergency, control panels can trigger safety alarms, unlock emergency exits, and alert security personnel. Furthermore, control panels can be programmed to activate fire suppression systems or adjust HVAC systems to prevent the spread of smoke, ensuring the safety of the building in crisis situations.

Remote Access and Automation

A significant advantage of modern control panels is the ability to provide remote access. With the integration of IoT (Internet of Things) technology, control panels can be accessed remotely via smartphones, tablets, or computers. This allows building managers to monitor and control various systems without being physically present. For instance, they can adjust the temperature, lighting, or security settings from anywhere in the world. This remote accessibility also allows for automation, where systems can be programmed to run autonomously based on pre-set parameters, such as automatically adjusting lighting when the sun rises or turning off HVAC systems when the building is empty.

Control panels are the cornerstone of smart building automation systems, enabling centralized control, energy efficiency, improved safety, and enhanced occupant comfort. These intelligent systems are not only designed to make the building’s environment more convenient but also to optimize resource usage and reduce operating costs. As technology continues to evolve, control panels are becoming smarter and more integrated, offering advanced features like real-time diagnostics, energy optimization, and remote management. For anyone looking to optimize the performance and efficiency of a building, investing in a well-designed control panel is an essential step toward achieving a smarter, more sustainable future.

Pulse Control offers an all-encompassing solution for control panel design, focusing on both technical excellence and customer satisfaction.

1. Custom Solutions for Every Industry

Pulse Control provides bespoke control panel design services, tailored to the unique needs of different industries, including industrial automation, oil & gas, renewable energy, water treatment, building automation, and more. Whether you need a basic control panel for a small system or a complex panel for an extensive, multi-layered operation, Pulse Control can design and deliver a solution that fits your exact requirements.

2. Expert Engineers with Vast Experience

With years of experience in the field, Pulse Control’s engineers bring both technical expertise and practical knowledge to the table. From the initial design concept to the final installation and commissioning, their team is equipped to handle every aspect of control panel design, ensuring that all elements function harmoniously. The engineers at Pulse Control keep up with the latest trends and technological advancements, which means you benefit from cutting-edge solutions.

3. Quality and Compliance Assurance

At Pulse Control, quality is paramount. They adhere to the highest standards of quality control, ensuring that every panel they design is durable, reliable, and meets international regulatory standards. All components used in the panels are sourced from reputable manufacturers, guaranteeing their long-lasting performance. Additionally, Pulse Control’s control panels are designed to meet industry-specific compliance requirements, ensuring safety, efficiency, and minimal downtime.

4. Cutting-Edge Technology Integration

Incorporating the latest technology is key to staying ahead of the curve, and Pulse Control excels in this aspect. The company integrates advanced features like smart control systems, HMI (Human-Machine Interface) displays, IoT connectivity, and remote monitoring in their control panel designs. These innovations allow businesses to gain real-time insights into their operations and provide predictive maintenance capabilities, minimizing the risk of unexpected failures.

5. User-Friendly and Efficient Designs

A great control panel is not just about functionality—it’s also about usability. Pulse Control understands the importance of user experience in control panel design. Their designs are intuitive and easy to navigate, allowing operators to control complex systems with ease. The layout is organized and clearly marked, with color-coded wiring, clear labeling, and accessible components. This user-centric approach minimizes human error and enhances the overall efficiency of operations.

6. Turnkey Solutions

Pulse Control offers complete turnkey solutions for control panel design, which means they manage the entire process, from concept to commissioning. This full-service approach includes panel design, component sourcing, assembly, testing, and installation. Customers can rest assured that every aspect of the control panel will be handled professionally, with no need to deal with multiple suppliers or contractors.

7. Cost-Effective and Timely Deliveries

Pulse Control takes pride in offering cost-effective solutions that never compromise on quality. Their efficient design and manufacturing processes ensure that you get the best value for your investment. Moreover, they are committed to meeting project deadlines, delivering your control panel on time, every time, so you can keep your operations running smoothly.

In an era where automation, precision, and reliability are crucial to business success, Pulse Control stands at the forefront of control panel design services. Their commitment to quality, innovation, and customer satisfaction makes them an invaluable partner for businesses looking to streamline operations and enhance efficiency. By choosing Pulse Control, you are investing in a solution that is both customized and future-proof, designed to meet your needs today and evolve with your operations in the future.

With a deep understanding of industrial demands and cutting-edge technological integration, Pulse Control is your trusted partner for all control panel design needs. Whether you’re looking for a simple solution or a complex, multi-functional control system, Pulse Control’s expertise and dedication to excellence ensure that your project will be in capable hands.