control panel

Control Panel: An Essential Component in Automation and Industrial Systems

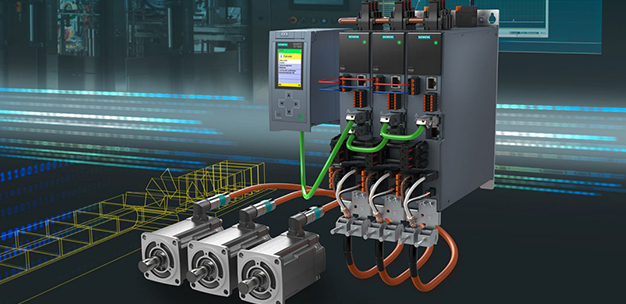

A control panel is a vital component in managing and operating electrical systems in various industries. It is essentially a centralized unit that houses electrical and electronic components such as switches, circuit breakers, controllers, and meters, which are used to monitor and control different machinery, equipment, or processes. Control panels are integral in industrial automation, offering efficient, safe, and streamlined control over machinery, ensuring optimal performance and safety.

Pulse Control as a Supplier of Control Panels in the UAE and Other Emirates

Pulse Control has earned a solid reputation as a key supplier of control panels across the United Arab Emirates (UAE) and other Emirates, offering innovative solutions tailored to a wide range of industries. The UAE, with its booming industrial, commercial, and technological sectors, requires high-quality, reliable, and efficient control systems for its various operations. Pulse Control meets this demand by providing control panels that are designed for seamless integration, enhanced performance, and long-term reliability. Here’s a deeper look into Pulse Control’s significance in the UAE and other Emirates.

1. Serving a Diverse Range of Industries in the UAE

Pulse Control’s presence in the UAE spans across a variety of industries, including manufacturing, automation, construction, energy, and transportation. The UAE’s rapid industrialization and ambitious infrastructure projects demand highly efficient control systems that can manage complex processes, from heavy machinery to intricate conveyor systems. Pulse Control’s control panels provide the infrastructure to manage these processes, ensuring that industries run smoothly and efficiently.

Whether it’s a large-scale project in the oil and gas sector or a manufacturing facility in one of the industrial zones in Dubai or Abu Dhabi, Pulse Control’s solutions are built to meet the specific needs of the UAE’s diverse industries. Their ability to offer customized solutions ensures that even the most demanding projects have the necessary control systems in place to guarantee safety, reliability, and operational efficiency.

2. Customization to Meet Local Needs and Regulations

One of the key advantages Pulse Control offers in the UAE and other Emirates is the ability to provide tailored control panels that meet local industry requirements and compliance regulations. The UAE is known for its stringent regulatory standards in construction, safety, and energy management. Pulse Control takes great care in ensuring that their control panels adhere to these standards, including certifications such as ISO, UL, and CE, which are crucial for maintaining safety and meeting regulatory requirements.

By collaborating closely with clients, Pulse Control ensures that the control panels are customized to suit the operational needs of the specific industry, considering factors like environmental conditions, scalability, and the complexity of the processes being controlled. This level of customization ensures that businesses in the UAE are equipped with control systems that meet both local needs and global best practices.

3. Advanced Technology and Automation Solutions

The UAE is at the forefront of embracing modern technology, particularly in the realms of automation and smart city development. Pulse Control plays a vital role in this technological transition by providing control panels that support advanced automation systems. Their panels incorporate the latest technologies in programmable logic controllers (PLCs), variable frequency drives (VFDs), remote monitoring, and Internet of Things (IoT) connectivity, which are essential for industries looking to optimize their processes and achieve greater efficiency.

Control panels from Pulse Control enable real-time monitoring, remote access, and predictive maintenance, reducing the need for manual intervention and allowing companies to streamline operations. These panels are particularly important in the UAE’s push for automation in sectors like manufacturing, energy, transportation, and logistics, where precision and efficiency are paramount.

4. Reliability and Durability for Harsh Environments

The UAE’s extreme weather conditions, with high temperatures and dust exposure, present unique challenges for industrial equipment. Pulse Control understands the need for reliable, durable systems capable of functioning in these harsh environments. Their control panels are designed with high ingress protection (IP ratings) to shield against dust, moisture, and extreme temperatures, ensuring continued performance in challenging conditions.

For industries operating in harsh outdoor environments, such as oil refineries, construction sites, and power plants, Pulse Control offers rugged control panels that stand up to these environmental stresses. This durability ensures minimal downtime, reducing operational interruptions and ensuring that critical processes continue uninterrupted.

5. Expert Support and After-Sales Services

Pulse Control provides comprehensive after-sales support, which is a significant factor in its success across the UAE and other Emirates. The company’s commitment to providing reliable and accessible support ensures that clients receive continuous assistance with troubleshooting, maintenance, and system upgrades. Whether it’s providing technical assistance or offering remote monitoring to troubleshoot issues, Pulse Control’s customer service team is ready to support businesses in maintaining the performance of their control panels.

Furthermore, Pulse Control’s engineers and technical experts work closely with clients during the installation and commissioning phases, offering valuable insights to ensure smooth operation. This hands-on support and expertise contribute to the company’s reputation as a trusted supplier in the UAE.

6. Meeting the Demands of the UAE’s Construction Boom

The UAE is renowned for its ambitious construction projects, including skyscrapers, transportation infrastructure, and large residential developments. Control panels play a vital role in managing the automated systems within these projects, from managing HVAC (heating, ventilation, and air conditioning) systems to controlling elevators, lighting, and security systems. Pulse Control’s customized control panels are essential in ensuring the efficiency and safety of these systems, particularly in high-rise buildings and large commercial spaces.

With the UAE’s continuous growth in urban development, Pulse Control’s solutions are integral in meeting the complex demands of construction projects. Their control panels offer the flexibility to manage multiple systems within a building, improving energy efficiency, reducing operational costs, and ensuring occupant safety and comfort.

7. Contributing to the UAE’s Energy and Sustainability Goals

As part of the UAE’s efforts to diversify its economy and move towards sustainable energy, Pulse Control is helping industries adopt more energy-efficient practices. Control panels with integrated energy management features are essential for reducing power consumption and optimizing energy use in both industrial and commercial sectors.

Pulse Control’s solutions allow businesses to monitor energy consumption in real-time, identify inefficiencies, and adjust operations to reduce waste. This aligns with the UAE’s national vision of sustainability, reducing the carbon footprint of industries and contributing to the country’s green energy initiatives.

Pulse Control plays a crucial role in supplying control panels that support the UAE’s thriving industries, from construction and manufacturing to energy and transportation. With a commitment to high-quality, customizable, and technologically advanced solutions, Pulse Control is well-positioned to meet the dynamic needs of the UAE and its neighboring Emirates. By offering durable, efficient, and scalable control systems, Pulse Control helps businesses enhance productivity, reduce downtime, and achieve their operational goals. As industries in the UAE continue to grow and innovate, Pulse Control remains a trusted partner, empowering businesses to keep pace with the rapidly evolving market landscape.

1. Components of a Control Panel

Control panels come in different configurations based on their application and can be categorized into different types, such as motor control panels (MCC), distribution panels, and automated control panels. Common components found in control panels include:

- Programmable Logic Controllers (PLCs): These are used for automation purposes, allowing complex operations to be programmed.

- Relays: Used to control circuits by opening and closing contacts.

- Circuit Breakers: Provide overcurrent protection, ensuring the safety of the electrical system.

- Switches and Pushbuttons: Used for manual control or to start and stop systems.

- Meters: Monitor various parameters such as voltage, current, and power.

- VFDs (Variable Frequency Drives): Used to control motor speed and energy usage.

2. Types of Control Panels

- Motor Control Panels (MCC): These panels control the operation of electric motors in industrial settings, including their start/stop operations, overload protection, and other operational controls.

- Automated Control Panels: These are used in fully automated systems, integrating various sensors, actuators, and controllers to enable real-time adjustments and monitoring.

- Power Distribution Panels: These manage the distribution of electrical power across various circuits in a system, ensuring proper load balancing and safety.

- PLC Panels: Contain PLCs and are designed for programmable automation tasks, often used in manufacturing, packaging, and processing plants.

3. Importance of Control Panels in Industry

Control panels are essential for the seamless operation of automated processes in industries such as manufacturing, energy, transportation, and utilities. They ensure that all processes are running smoothly, from managing the flow of materials on conveyor belts to controlling the power distribution in a plant. By centralizing control, these panels make it easier for operators to monitor and adjust settings quickly and efficiently.

- Automation: Control panels are fundamental in automation systems, helping industries reduce labor costs and increase production efficiency. For instance, in a manufacturing plant, a control panel can manage everything from temperature control in furnaces to the movement of machinery, ensuring precision and reducing human error.

- Safety and Protection: Control panels ensure that equipment is running safely by incorporating various safety features such as circuit breakers, overload relays, and emergency stop buttons. These features protect both the equipment and the personnel from electrical hazards or faults.

- Remote Monitoring: Many modern control panels come equipped with remote monitoring capabilities, allowing operators to track system performance and diagnose issues from anywhere. This feature is particularly important for industries where downtime needs to be minimized, and maintenance can be scheduled proactively.

4. Advantages of Control Panels

- Increased Efficiency: Control panels allow for efficient monitoring and control of complex systems, enabling industries to streamline operations and reduce manual intervention.

- Improved Safety: By centralizing control and offering various protective measures, control panels minimize the risk of accidents and ensure compliance with safety regulations.

- Customization: Control panels can be customized to meet the specific needs of different industries. This ensures that systems are tailored to operational requirements, improving performance and efficiency.

- Reduced Downtime: With advanced diagnostic features, control panels can quickly identify faults, allowing for timely maintenance and minimizing costly downtime.

5. Applications of Control Panels

Control panels are widely used across different sectors:

- Manufacturing: For managing automation processes, machinery control, and material handling systems.

- Power Plants: To control electrical generation and distribution systems.

- Construction: For controlling systems like HVAC (Heating, Ventilation, and Air Conditioning), lighting, and security systems in commercial buildings.

- Oil and Gas: To manage automated processes in refineries, pipelines, and drilling operations.

- Transportation: For controlling systems like traffic lights, railway signaling, and elevator systems.

Control panels are an indispensable part of industrial and commercial operations, providing centralized management, safety, and control for electrical and mechanical systems. With the rise of automation and smart technology, modern control panels offer greater flexibility, real-time monitoring, and enhanced functionality, making them essential for industries striving for efficiency and safety. Whether in a factory, a power plant, or a construction site, control panels play a crucial role in keeping systems running smoothly and ensuring the safety of equipment and personnel.